Machining, prototyping and more from Sigma Machine

The lynchpin of Sigma Machine's success is our diverse, multitalented design team. All highly-experienced in taking concepts through the entire manufacturing process, our team possesses an innovative thinking process and has full access to Sigma Machine's state-of-the-art production capabilities. With extensive experience working with plastic and non-ferrous materials, we specialize in stainless steel machining and prototyping, as well as aluminum prototyping and machining.

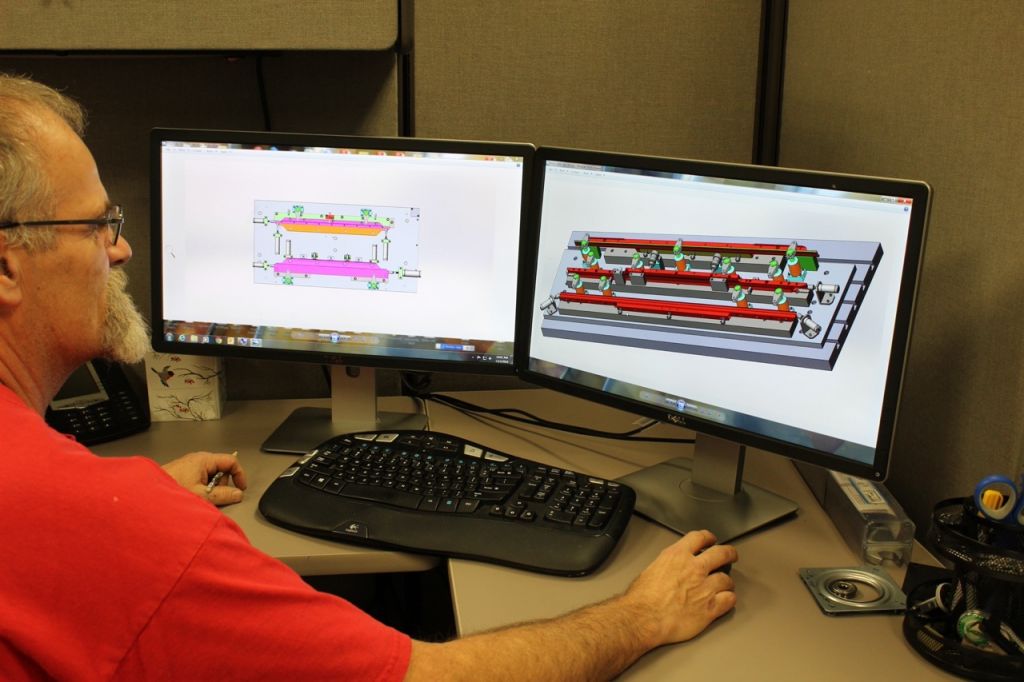

Design / Engineering / Consulting

Our design team utilizes Solid Works and has the ability to work with Pro-E, Catia and AutoCAD. We provide design, DFM study, as well as CAD design assistance. Additionally, we have probe and laser digitizing capabilities. If you can imagine it, we can put it on paper.

Prototyping

Sigma Machine can make a scaled-up version of your component or project. Once completed, you can reliably plot revisions, discuss production specifics and create an accurate budget. Whether you need a stainless steel or aluminum prototype, we can make it happen.

Quality Systems

At Sigma Machine, we take pride in providing superior quality parts and service. We offer state-of-the-art CMM capabilities, vision systems and leak testers to ensure that we meet our clients' expectations. Our in-house systems meet – and exceed – tier 1 automotive requirements.

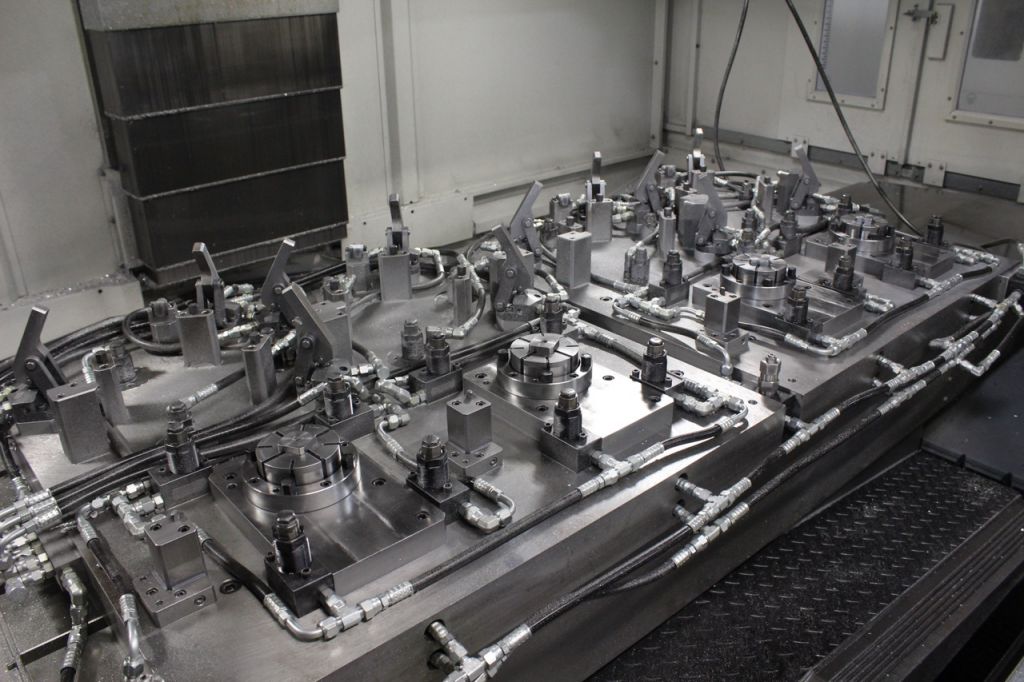

Fixturing

Designing and building both PLC-controlled pneumatic and hydraulic actuated fixtures in house, Sigma Machine's fixturing capabilities are unmatched. Driven to achieve the highest levels of quality possible, our team adopts a can-do attitude when it comes to finding innovative solutions.

Production

Sigma Machine's production capabilities are what sets us apart. Utilizing multi-spindle, multi-axis machines and specializing in stainless steel and aluminum, our passion lies in these two mediums. We can also work with plastics of various types, depending on your needs.

Assembly

From simple to complex, Sigma Machine's assembly capabilities aim to alleviate our clients' logistical burdens. With dedicated assembly space and a knowledgeable, quality-driven team, these services ensure that we deliver on what your project needs, from concept to completion.

Packaging

National and local packaging experts partner with Sigma Machine designing solutions to meet demanding customer specifications.

Fulfillment

At Sigma we take pride in our On-Time deliveries.

Design for Manufacturability

Sigma Machine doesn't want to simply create functional prototypes for our clients, we want to create prototypes that are easy to manufacture. Our DFM services work to eliminate problematic design elements and ensure that your product's manufacturing costs are within reason.